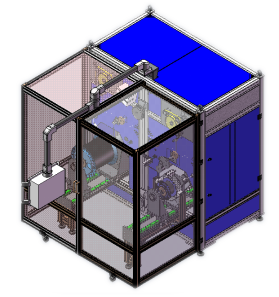

QY-GLS-12/238 Optical Fiber Secondary Coating Production Line

Application and Feature of Production Line

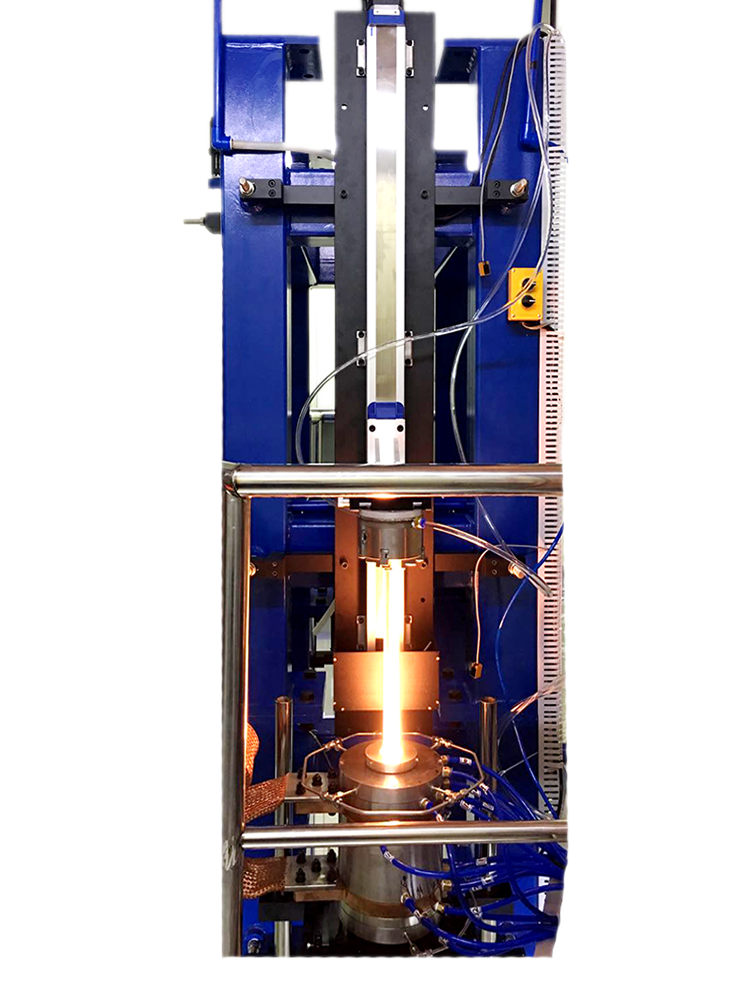

The optical fiber secondary coating production line is mainly used for extruding 2~12 cores optical fiber loose tube of Ф1.5~Ф3.0 mm OD and optical cable filling rope. The extrusion materials are suitable for PBT, PP, PC and PE. The extruded shape is round, uniform in diameter and smooth.

This line has the following features:

1)Production line structural design speed is 800M/Min, production speed: ≥500 ~ 600m/min (Ф1.80mm, wall thickness 0.30mm, PBT loose tube)

2)Residual length control range: 0~3 ‰.

3)In order to improve the stability and reliability of product, the cold water circulation system adopts automatic constant temperature control,and is equipped with a refrigeration device.

4)The optical fiber filling system has a constant temperature control device, so that the filling amount is accurate, stable and reliable.

5)The key electrical control components in production are all made of high quality products with reliable quality and are easy to maintain.

6)Extruder adopts type 60, aspect ratio is 25:1.

Overall Design Technical Specifications

| 1 |

Optical fiber pay-off reel number |

12 |

| 2 |

Optical fiber pay-off tension |

0.4~1.5N±0.05N |

| 3 |

Pay-off reel specification |

25km and 50km(two kinds of optical fiber reel) |

| 4 |

Loose tube diameter |

Φ1.5mm~Φ3.0mm |

| 5 |

Continuous production length |

up to 50KM |

| 6 |

Hot water tank temperature |

room temperature~80℃ |

| 7 |

Outlet water temperature of refrigerator |

15℃~25℃(adjustable) |

| 8 |

Line diameter deviation |

±0.03 |

| 9 |

Residual length control range |

0~3‰ |

| 10 |

Residual length control accuracy |

±0.2‰ |

| 11 |

Length meter charge difference |

≤0.2% |

| 12 |

Additional loss at room temperature after coating |

≤0.02dB/km(average value 0.01 dB/km) |

| 13 |

Whole line power |

≈60KW |

| 14 |

Production direction |

contract agreement |

| 15 |

Equipment color |

customer-specified |